#Jerry dunlap crackerbox plans how to#

Any ideas how to re-coil it?Īccording to Aircraft Spruce's plywood list the 3mm is 1/8" which is what you want.You can use it for the hull bottoms as well as the deck.What are your frames made of? The 3mm would work for them also. Is that OK?Īlso, i un-coiled the starter when trying (unsuccessfully) to convert to a cordless drill starter. I've glued in little cubes of pine, as reinforcement:Ĭut out all the stringers! Instead of following the plan, I'm thinking of simply using 6圆mm stringers all round (instead of 5x10mm on the top&bottom). Hmm maybe penrith isn't going to be tough enough for us then! (kidding) haha - i may be able to sweet talk it, given that a souped-up zenoah would put out more power i'm guessing. Isnt epoxy the same as fibreglass resin? I hope to encapsulate it, but epoxy is so expensive so if anyone can suggest an alternative that'd be great! I don't think they will let you run a 50cc at Penrith ether, up to 35cc is ok though.

#Jerry dunlap crackerbox plans crack#

I would suggest encapsulating with epoxy or fiberglass resin, paint will crack and let water in. This is how i'm holding the keel vertically, a nice thick chunk of wood is very useful for this: Now i'm gluing the bulkheads into position: Plan to later encapsulate the whole lot in paint to avoid water ruining the glue.Īnd some precariously balanced weights adding pressure to the glue as it dries. Heres the 'scab' gluing the front and rear keels together. Had to use the plans to line up the front and rear keels correctly: You can see a bit where i sawed a bit too much off. To get them smooth, i had to run it carefully through the table saw. Here you can see how i've sandwiched the 5 front keels together. Hopefully stiff enough to handle a pocket bike engine.Īnd here i'm holding the keel (left piece of timber) which is 5 pieces of ply glued together. Here's the nosepiece, with the 2 doublers on each side (4 doublers total) making it 15mm wide. Lots of cut out bits on 3mm ply bought from bunnings:

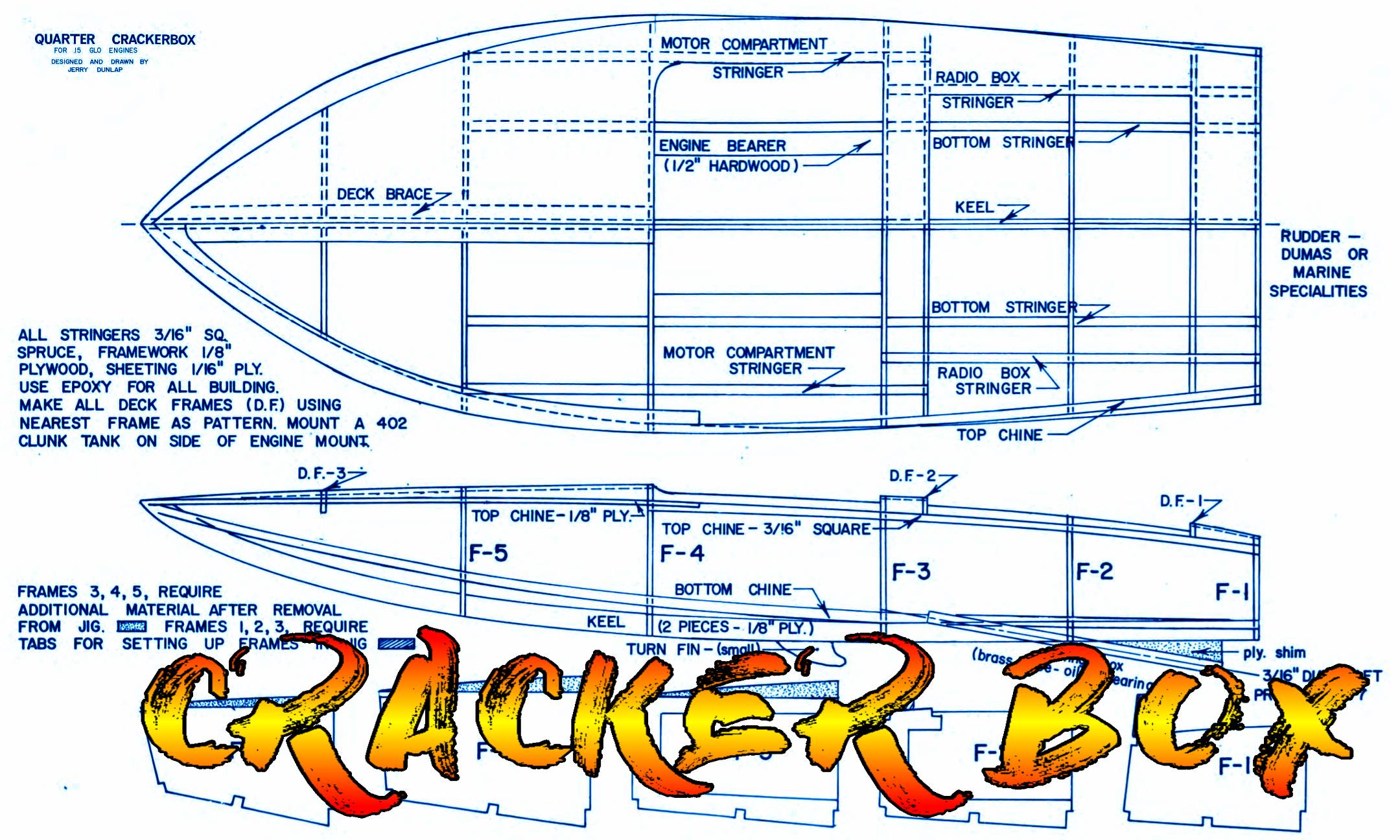

In hindsight, i should have gone with the a kit from zippkits! The plans are alright, not much description to go with them unfortunately.

I'm a beginner here so no offence will be taken unless you're super rude about it. Hi all, I'm building a crackerbox from the jerry dunlap plans and i thought I'd post my build here and get tips as i go.Īnd PLEASE give me advice as i go - especially with the 'next step' as you see it coming.

0 kommentar(er)

0 kommentar(er)